Creating clear and accurate electrical schematics is a critical part of product development. For engineers and designers working with complex electromechanical systems, the ability to visualize and document wiring is paramount. This is where the concept of a Solidworks Wiring Diagram becomes invaluable, offering a robust solution for electrical design within a familiar 3D modeling environment.

Understanding Solidworks Wiring Diagrams

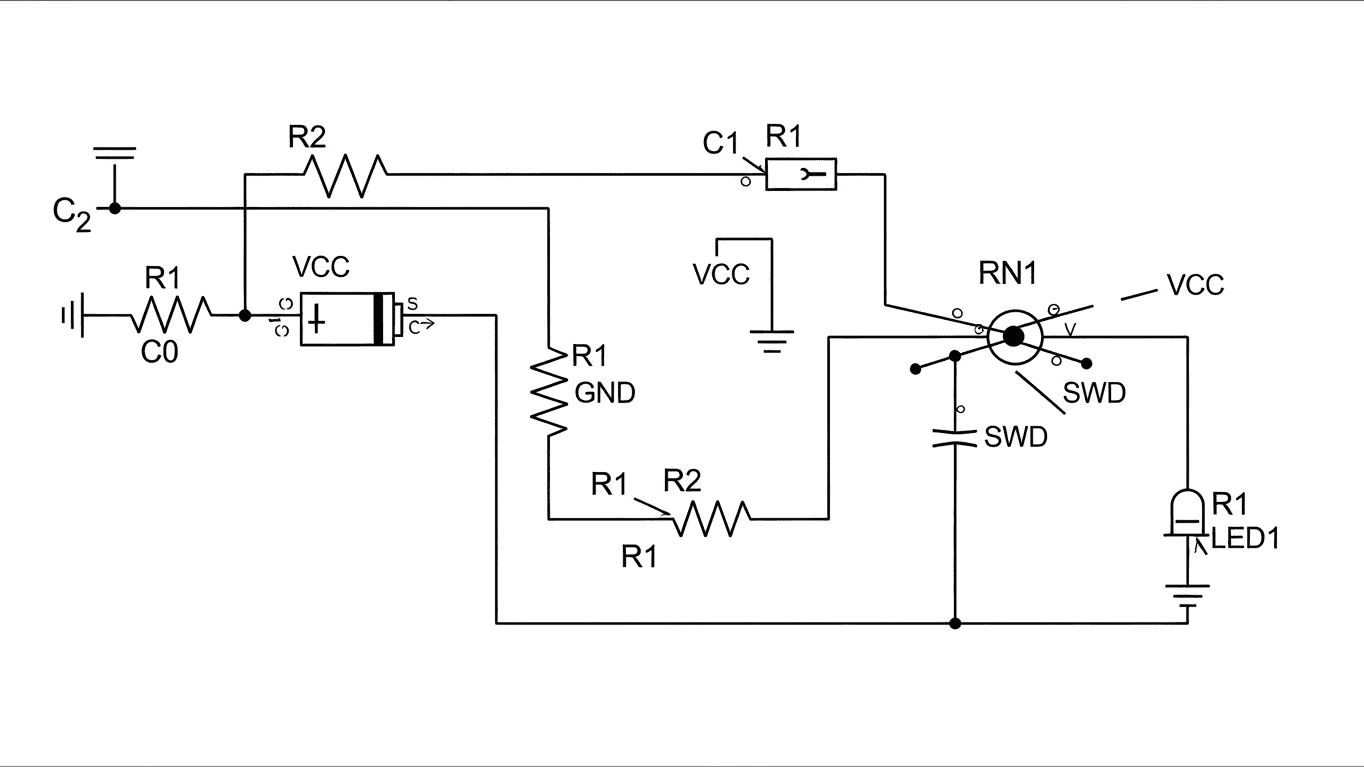

A Solidworks Wiring Diagram is essentially a visual representation of the electrical connections within a product or system. It's a schematic that details how wires, cables, connectors, and electrical components are interconnected. Unlike purely mechanical drawings, these diagrams focus on the electrical pathways, ensuring that power flows correctly and that all components are linked as intended. This meticulous documentation is essential for several key reasons:

- Troubleshooting: When issues arise, a clear wiring diagram acts as a roadmap to quickly identify the source of the problem.

- Manufacturing: Assembly line workers rely on these diagrams to correctly wire components, minimizing errors and rework.

- Maintenance and Repair: Technicians can use the diagram to understand how the system is put together, making repairs more efficient.

- Design Verification: Engineers can review the diagram to ensure the electrical design meets all specifications and safety standards.

The power of using Solidworks for wiring diagrams lies in its integration with the 3D design environment. This means that electrical components and their corresponding physical representations in the 3D model can be linked. When you place an electrical connector in your schematic, you can associate it with the actual connector model in your assembly. This bi-directional associativity ensures that changes made in one place are reflected in the other. This interconnectedness allows for:

- Accurate Wire Length Calculations: By linking schematic wires to physical routes in the 3D model, Solidworks can automatically calculate exact wire lengths.

- Component Placement Verification: The diagram helps confirm that all necessary electrical components have been accounted for in the 3D assembly.

- Harness Design Automation: Complex wiring harnesses can be generated more efficiently, saving significant design time.

The information presented in a Solidworks Wiring Diagram can be organized in various ways to suit different needs. Often, a table format is used to list components and their connections. For example:

| From Component | From Pin | To Component | To Pin | Wire Type |

|---|---|---|---|---|

| Motor M1 | P1 | Power Supply PS1 | OUT1 | 18 AWG |

| Sensor S1 | A1 | Controller C1 | IN2 | 22 AWG |

The ability to generate and manage these diagrams directly within Solidworks is a significant advantage for any company aiming for streamlined and error-free electromechanical product development.

To truly harness the capabilities of Solidworks for your electrical design needs, explore the dedicated tools and functionalities available within the software. These resources will provide you with the guidance and features necessary to create precise and effective Solidworks Wiring Diagrams.