A Split Phase Motor Wiring Diagram is an essential tool for anyone working with or maintaining these common types of single-phase AC electric motors. It visually represents the electrical connections required to make a split phase motor operate, detailing the starting winding, the running winding, and the centrifugal switch. Understanding this diagram is crucial for proper installation, troubleshooting, and repair.

What is a Split Phase Motor Wiring Diagram?

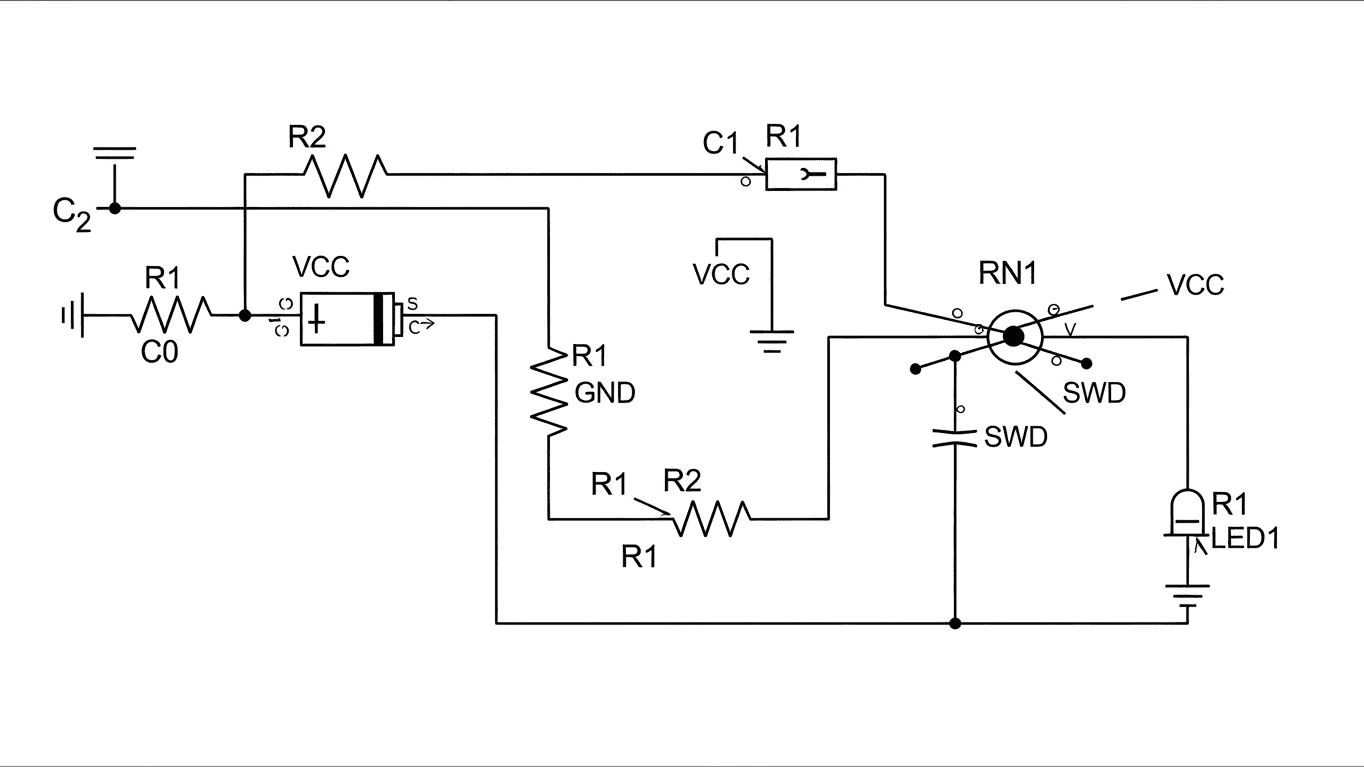

A Split Phase Motor Wiring Diagram illustrates the internal and external electrical pathways of a split phase motor. These motors are characterized by having two windings: a main (or running) winding and an auxiliary (or starting) winding. The starting winding is connected in series with a capacitor (in some variations) and a centrifugal switch. The diagram shows how these components are interconnected with the power supply. The accurate interpretation of a Split Phase Motor Wiring Diagram is paramount to ensuring the motor starts efficiently and runs reliably. Without it, connecting the motor could lead to damage or failure.

The primary purpose of the Split Phase Motor Wiring Diagram is to guide the correct wiring of the motor's components. The starting winding, with its higher resistance and lower reactance, creates a phase difference with the main winding. This phase difference is what generates the rotating magnetic field necessary for the motor to start turning. The centrifugal switch is a key element; it disconnects the starting winding and any associated capacitor once the motor reaches a certain speed, preventing damage and improving efficiency. Here's a breakdown of common components you'll find depicted:

- Power Supply Terminals

- Running Winding

- Starting Winding

- Centrifugal Switch

- Capacitor (if present)

These diagrams are used in a variety of applications, from household appliances like washing machines and fans to small industrial machinery. When installing a new motor, replacing a faulty one, or troubleshooting performance issues, referring to the specific Split Phase Motor Wiring Diagram for that model is the most effective approach. It acts as a blueprint, ensuring all connections are made according to the manufacturer's specifications. The complexity can vary, but the core principles remain consistent. Some diagrams might look like this:

| Component | Function |

|---|---|

| Running Winding | Provides continuous torque during operation. |

| Starting Winding | Provides initial torque to start the motor. |

| Centrifugal Switch | Disconnects the starting winding once the motor is up to speed. |

If you need to understand the specific connections for your split phase motor, consult the diagrams provided in the manual or on the motor's nameplate. This resource will offer the precise layout required for a safe and functional setup.