Understanding the Start Stop Contactor Wiring Diagram is crucial for anyone working with electrical control systems, especially in industrial settings. This diagram serves as a blueprint, detailing how to connect the components that allow for the safe and effective operation of machinery. A well-understood Start Stop Contactor Wiring Diagram ensures that motors and other equipment can be reliably turned on and off with the press of a button.

What is a Start Stop Contactor Wiring Diagram and How is it Used?

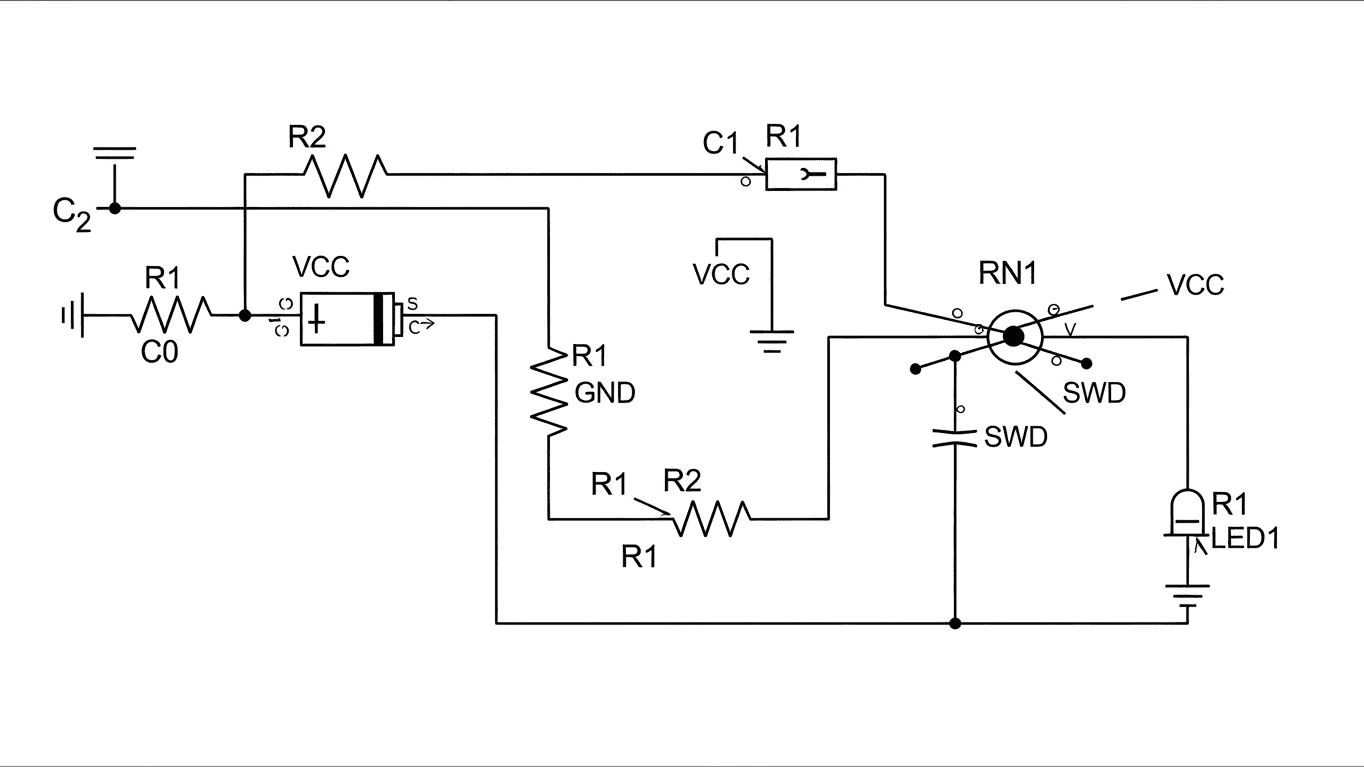

At its core, a Start Stop Contactor Wiring Diagram illustrates the connections between a start button, a stop button, and one or more contactors. Contactors are heavy-duty relays designed to switch high-power circuits, typically used to control electric motors. The start button, when pressed, energizes the coil of a control relay or directly the contactor coil, causing it to close its main contacts and supply power to the motor. Simultaneously, a set of auxiliary contacts on the contactor often 'latch in', maintaining the circuit even after the start button is released.

The stop button, usually a normally closed (NC) pushbutton, is wired in series with the start button and the contactor coil. When the stop button is pressed, it breaks the control circuit, de-energizing the contactor coil. This causes the main contacts to open, cutting power to the motor and stopping it. The inclusion of both start and stop buttons provides a direct and intuitive method for operators to control equipment. Here's a simplified breakdown of the components involved:

- Start Pushbutton: Momentary contact, normally open (NO).

- Stop Pushbutton: Momentary contact, normally closed (NC).

- Contactor: An electrically controlled switch for high-current circuits.

- Overload Relay (often included): Protects the motor from overcurrent conditions.

The typical operation can be visualized with a sequence. When the start button is pushed, the circuit path to the contactor coil is completed. The contactor pulls in, closing its power contacts and energizing the motor. A holding or latching contact associated with the contactor then bypasses the start button, keeping the contactor energized. To stop the motor, pressing the stop button opens the control circuit, de-energizing the contactor coil. The holding contact then opens, and the main power contacts also open, stopping the motor. The proper implementation of the Start Stop Contactor Wiring Diagram is vital for operator safety and equipment longevity.

Here's a look at a basic wiring scenario. Imagine a single motor control circuit. The power source feeds into the control circuit. The stop button (NC) is wired first, followed by the start button (NO). After the start button, a set of normally open auxiliary contacts from the contactor (the holding contacts) are wired in parallel with the start button. This entire series, including the stop button, start button, and holding contacts, is connected to one side of the contactor coil. The other side of the contactor coil is connected to the neutral or common return. The main power contacts of the contactor are wired in series with the motor and the incoming power supply.

To get a clear understanding of how to implement this system correctly, refer to the specific Start Stop Contactor Wiring Diagram provided for your application. The detailed schematics will outline the exact placement of each component and the precise connections required.

For a complete and accurate representation of how to wire your specific start stop system, please consult the detailed diagrams and technical documentation provided with your equipment or consult with a qualified electrician. These resources will offer the precise schematics necessary for a safe and functional installation.