A Stator Wiring Diagram is an essential tool for anyone working with electrical systems, especially in machinery and vehicles. It visually represents how the stator's coils are connected to the rest of the electrical components. Understanding this diagram is crucial for troubleshooting, repair, and even basic maintenance. Without a clear Stator Wiring Diagram, diagnosing electrical issues can be a frustrating and time-consuming process.

What is a Stator Wiring Diagram and How is it Used?

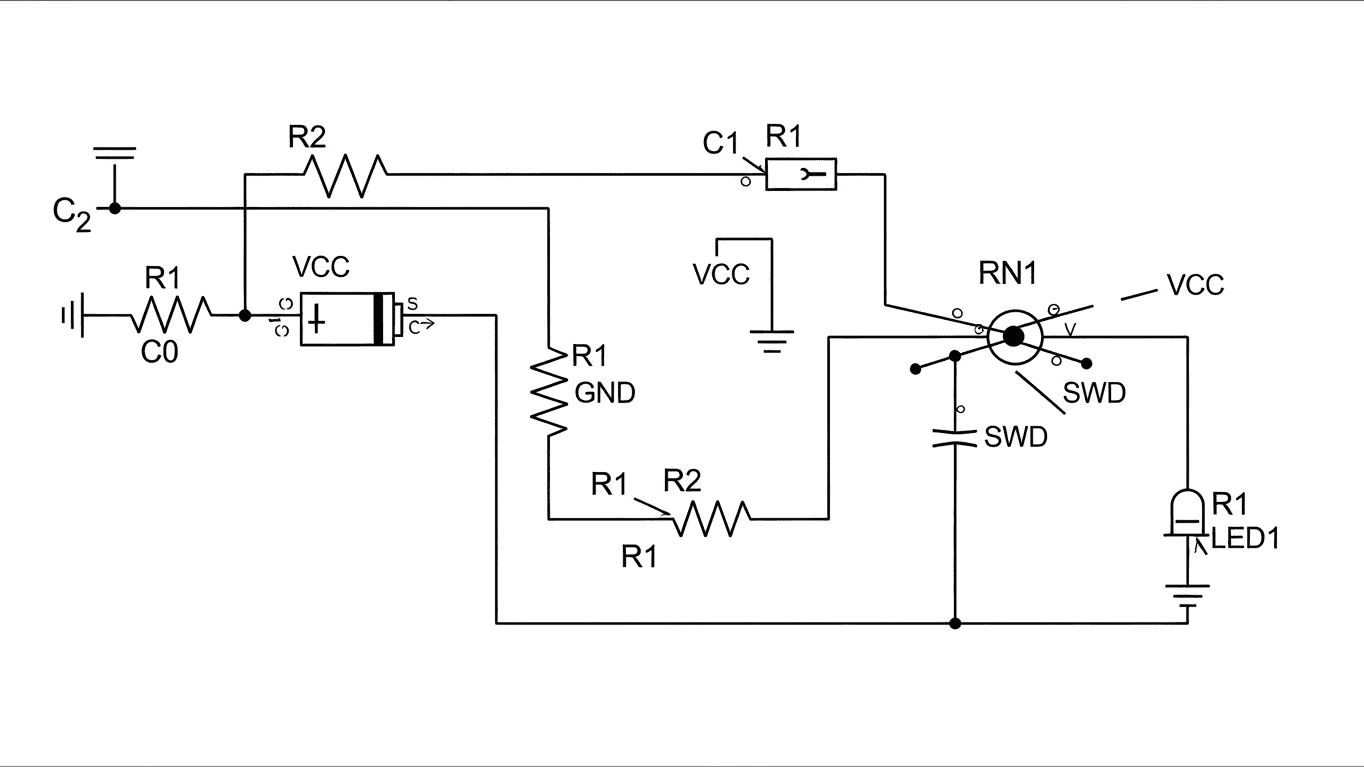

At its core, a Stator Wiring Diagram is a schematic that illustrates the internal connections of a stator, which is a stationary part of an electric motor or generator containing coils of wire. These coils are responsible for generating or responding to magnetic fields. The diagram shows how these individual coils are linked together – whether in series, parallel, or a combination of both – and where they connect to external circuits, such as the rectifier, regulator, or battery. This visual representation is the universal language for electricians and technicians when discussing and working on stator-related electrical problems.

The primary use of a Stator Wiring Diagram is for diagnosing faults. When an electrical system powered by a stator isn't functioning correctly, the diagram allows for systematic testing. Technicians can trace the expected flow of current and identify points of failure. For example, the diagram might indicate:

- The number of stator windings.

- The color coding of the wires coming from the stator.

- The termination points for each winding.

- Common connection configurations.

The importance of having the correct Stator Wiring Diagram cannot be overstated when attempting any repair or modification. It ensures that connections are made precisely as intended by the manufacturer. Incorrect wiring can lead to component damage, reduced performance, or complete system failure. Furthermore, understanding different configurations can be vital for performance upgrades or when replacing a stator with a different, yet compatible, unit. Some common configurations include:

- Wye (Y) connection: Where three separate windings meet at a common neutral point.

- Delta (Δ) connection: Where the windings are connected end-to-end in a triangular fashion.

A simplified table might show the expected resistance values between different stator terminals, which is a key diagnostic step:

| Connection Points | Expected Resistance (Ohms) |

|---|---|

| Terminal A to Terminal B | 0.5 - 1.0 |

| Terminal B to Terminal C | 0.5 - 1.0 |

| Terminal C to Terminal A | 0.5 - 1.0 |

To effectively use and interpret your specific Stator Wiring Diagram, it's best to refer to the documentation provided with your equipment or vehicle. This will ensure you have the most accurate and relevant information for your particular application.