Understanding a Stepping Motor Wiring Diagram is crucial for anyone looking to harness the precise control offered by stepper motors. Whether you're building a DIY CNC machine, a robotics project, or a 3D printer, knowing how to correctly wire your stepper motor is the first step towards success. This guide will break down the essentials of a Stepping Motor Wiring Diagram.

Demystifying the Stepping Motor Wiring Diagram

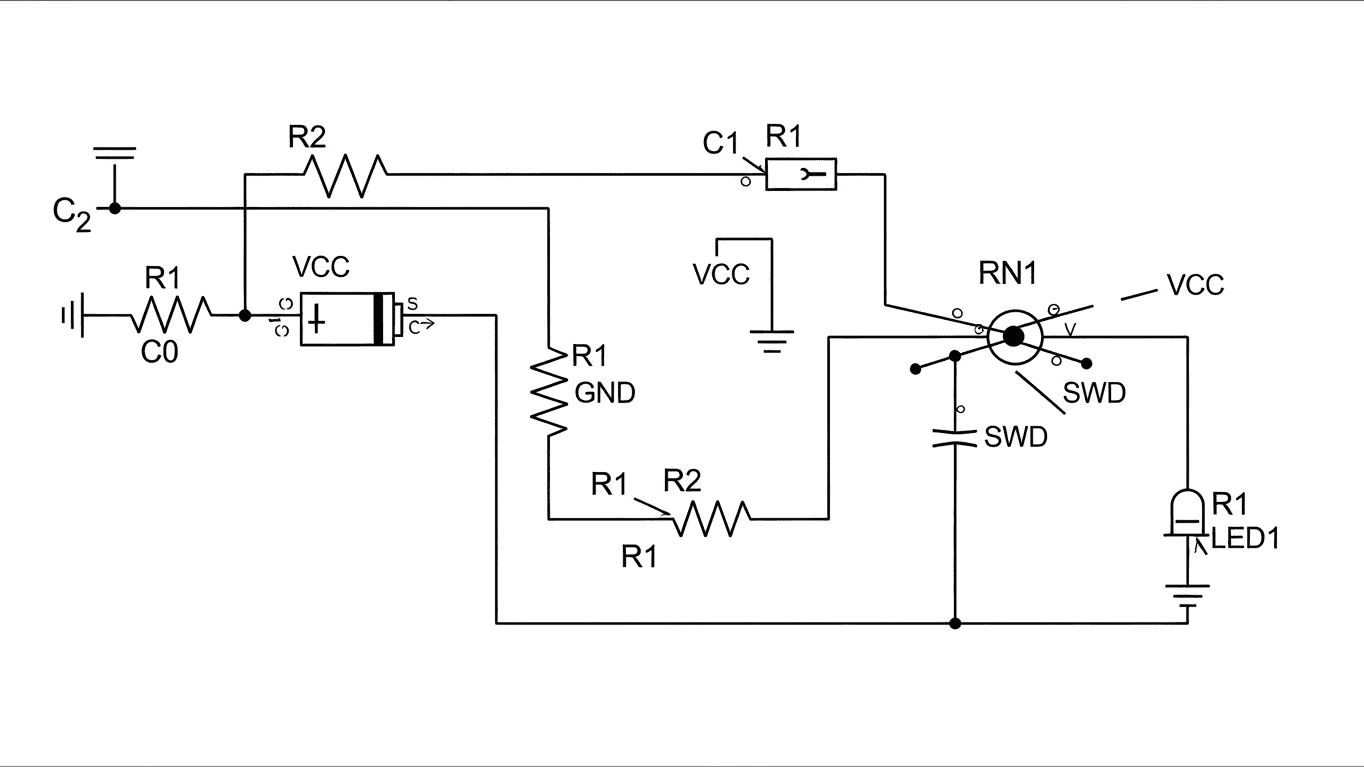

A Stepping Motor Wiring Diagram is essentially a blueprint that shows how to connect the electrical wires of a stepper motor to a motor driver or controller. Stepper motors work by dividing a full rotation into a number of equal steps. By energizing different coils in a specific sequence, the motor shaft rotates in precise increments. The wiring diagram dictates which coil to energize and in what order to achieve this controlled movement. Without a clear understanding of this diagram, you risk damaging your motor or driver, or simply not getting the expected performance.

Stepper motors typically have multiple wires, usually four, six, or eight, corresponding to their internal windings. These windings are arranged in phases, and the driver sends pulses of current to these phases to make the motor move. A common four-wire bipolar stepper motor has two windings (Phase A and Phase B), with each winding having two wires. A six-wire unipolar stepper motor has three windings, with two wires per winding, and often has center taps that can be used for bipolar operation or left unconnected for unipolar. The Stepping Motor Wiring Diagram will clearly label these wires and indicate their connection points on the driver. The importance of correctly identifying these wires cannot be overstated; a single misconnection can prevent the motor from working or even cause permanent damage.

Here's a simplified look at how different stepper motor types are typically wired:

- Bipolar Stepper Motor (4 Wires): These motors have two independent windings. The wiring diagram will show pairs of wires belonging to each winding. For example, wires 1 & 2 might be for Phase A, and wires 3 & 4 for Phase B.

- Unipolar Stepper Motor (6 or 8 Wires): These have windings with center taps. A 6-wire unipolar motor usually has two sets of windings. The diagram will show the start and end wires for each winding, and the center tap. For an 8-wire motor, each winding is split into two, offering more flexibility in wiring for bipolar configurations.

When using a Stepping Motor Wiring Diagram, you'll often see symbols representing the motor coils and the driver's output pins. The diagram will connect these logically, guiding you through the process. Always refer to the specific diagram provided by the manufacturer of your stepper motor and your motor driver, as variations exist.

To ensure you have the most accurate and detailed information for your specific setup, we highly recommend consulting the detailed documentation and diagrams that came with your stepper motor and driver components. These resources are designed to provide precise guidance.