Understanding the intricacies of your submersible pump system starts with a clear grasp of its electrical heart. A Submersible Pump Wiring Diagram is your essential roadmap, detailing how power connects to your pump and its associated controls. Whether you're a homeowner with a well or a professional installer, having a reliable Submersible Pump Wiring Diagram is crucial for safe and efficient operation.

The Essential Blueprint: What is a Submersible Pump Wiring Diagram?

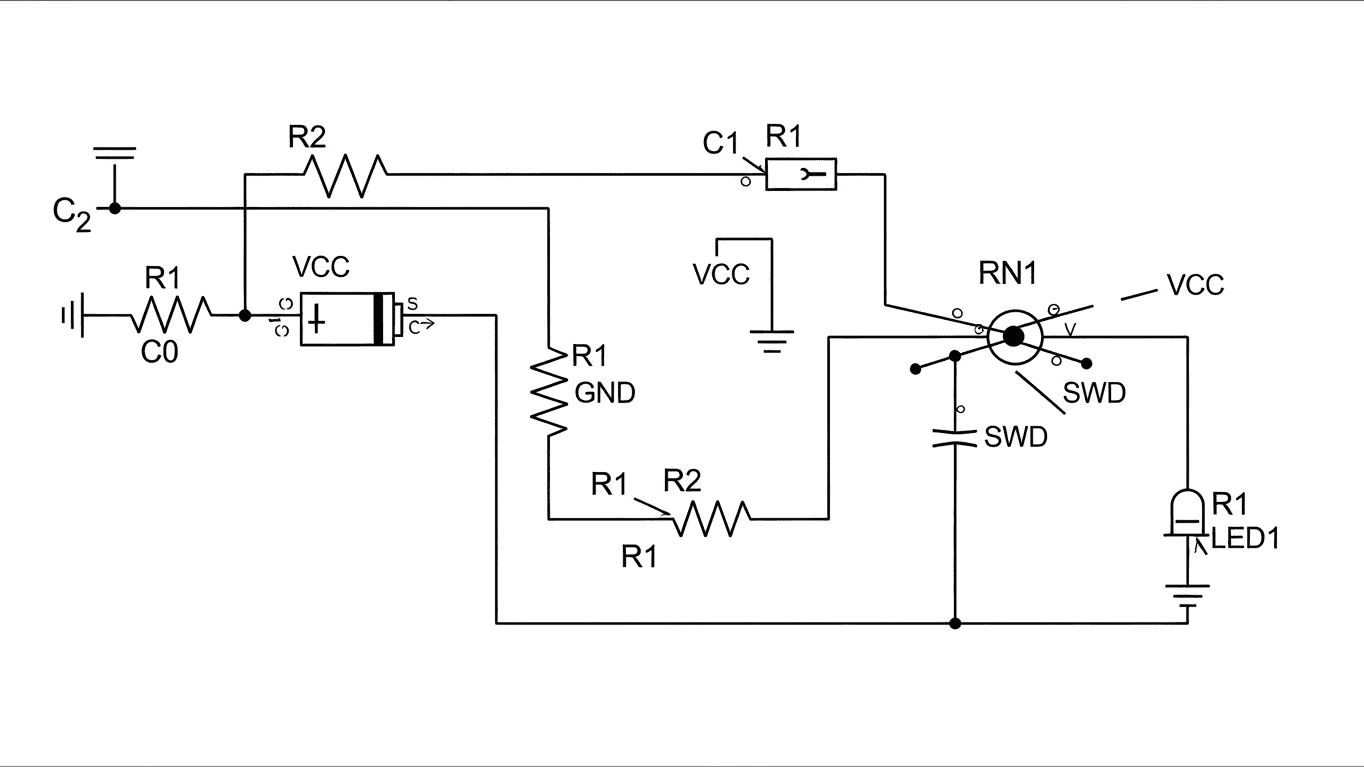

A Submersible Pump Wiring Diagram is a schematic representation that illustrates the electrical connections within a submersible pump system. It outlines the pathway of electricity from the power source, through protective devices, to the pump motor itself, and often includes controls like pressure switches or float switches. These diagrams are not just lines and symbols; they are a critical tool for diagnosis, repair, and proper installation, ensuring that all components are connected correctly and safely. The importance of following a Submersible Pump Wiring Diagram cannot be overstated, as incorrect wiring can lead to system failure, damage to the pump, and significant safety hazards.

These diagrams serve multiple vital purposes in the life cycle of a submersible pump. For installation, they provide the precise connections needed to get the pump up and running. During troubleshooting, they help pinpoint the source of electrical issues, whether it's a faulty connection, a blown fuse, or a problem with a control device. For maintenance, they offer a reference to ensure that any adjustments or replacements are made according to the manufacturer's specifications. Here are some common elements you'll find in a Submersible Pump Wiring Diagram:

- Power Source (e.g., utility power, generator)

- Disconnect Switch or Breaker

- Control Box (for some pumps)

- Pressure Switch

- Float Switch

- Pump Motor Terminals

- Capacitor (for single-phase motors)

- Grounding Wire

The complexity of a Submersible Pump Wiring Diagram can vary. A simple residential system might involve a straightforward connection from the power source to the pump via a pressure switch. More complex industrial applications may include multiple pumps, advanced control systems, and sophisticated safety interlocks. Regardless of complexity, the underlying principle remains the same: to clearly and concisely depict how the electrical energy is delivered to operate the pump effectively and safely. Here's a simplified look at the typical flow:

- Power enters the system through a main disconnect.

- The power then goes through protective devices like circuit breakers or fuses.

- Control devices, such as pressure switches that turn the pump on and off based on water pressure, are integrated into the circuit.

- Finally, the power reaches the pump motor, often through a control box that houses capacitors or other starting components.

To get a clear understanding of your specific system, always refer to the official Submersible Pump Wiring Diagram provided by the pump manufacturer. It's the most accurate and reliable source of information for your particular model.