Understanding a Tachometer Wiring Diagram Diesel is crucial for anyone working on diesel engines, especially when installing or troubleshooting a tachometer. This diagram provides the essential blueprint for connecting your tachometer correctly, ensuring accurate engine speed readings and preventing potential damage to your electrical system. A proper understanding of the Tachometer Wiring Diagram Diesel can save you time, money, and frustration.

What is a Tachometer Wiring Diagram Diesel and How It's Used

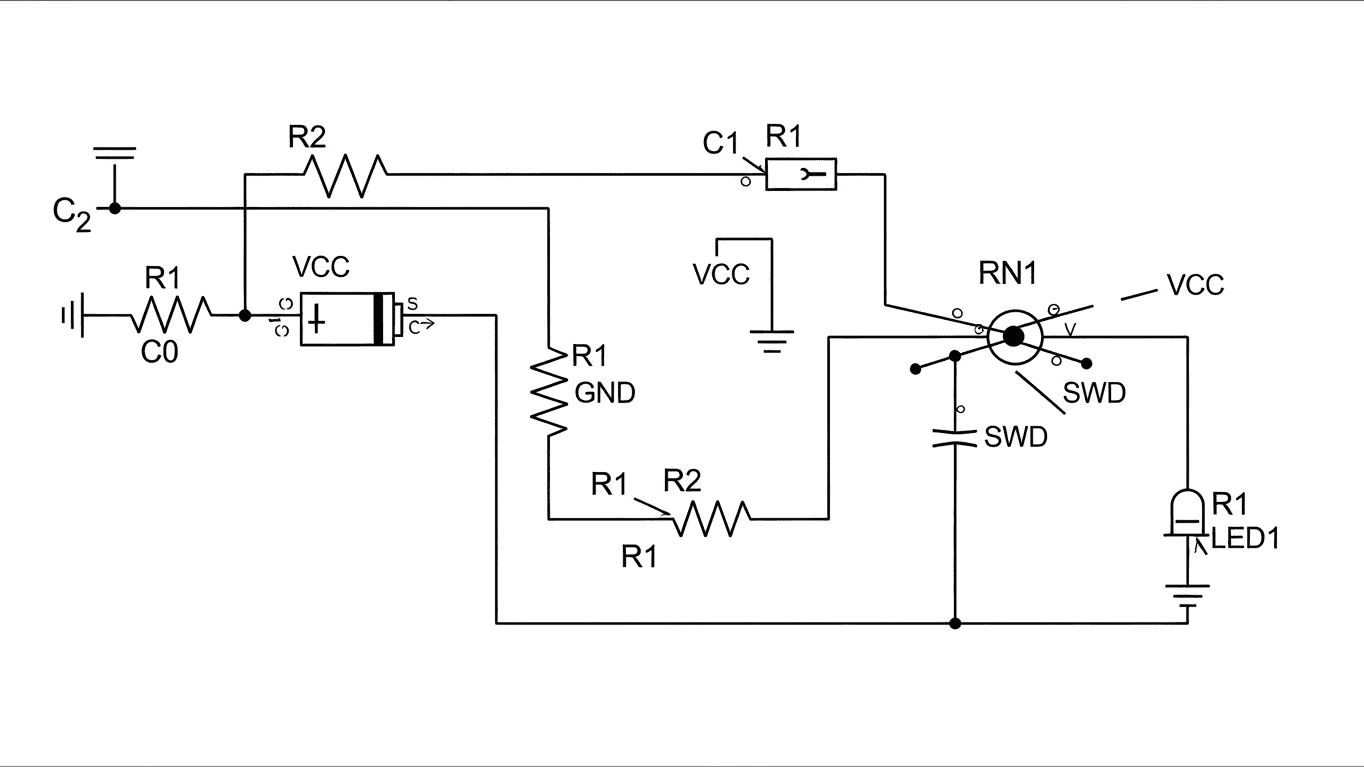

A Tachometer Wiring Diagram Diesel is a schematic that illustrates the electrical connections required to integrate a tachometer into a diesel engine's system. It shows where to connect the tachometer's wires to the engine's signal source, power, and ground. Without this diagram, connecting a tachometer would be guesswork, leading to incorrect readings or, worse, electrical faults. It's like trying to assemble furniture without instructions – it’s possible, but highly inefficient and likely to end poorly. The importance of using the correct Tachometer Wiring Diagram Diesel cannot be overstated for a reliable and functional tachometer.

Tachometers are used for several key reasons in diesel applications:

- Monitoring Engine Speed: The primary function is to display the revolutions per minute (RPM) of the engine. This is vital for optimal performance, fuel efficiency, and preventing engine over-revving.

- Diagnosing Engine Problems: Unpredictable or incorrect RPM readings can signal underlying issues with the engine's fuel system, governor, or other critical components.

- Performance Tuning: For those looking to optimize engine performance, the tachometer provides real-time feedback on how engine modifications affect RPM.

The connection points vary depending on the type of diesel engine and the tachometer itself. Generally, you'll find these common elements in a Tachometer Wiring Diagram Diesel:

-

Signal Source:

This is where the tachometer "reads" the engine's speed. Common sources include:

- Alternator "W" Terminal: Many older diesel engines use a dedicated terminal on the alternator.

- Engine Control Module (ECM): Modern engines often send a speed signal directly from the ECM.

- Crankshaft or Camshaft Position Sensor: These sensors provide crucial timing information that can be converted to RPM.

- Power (Ignition/Accessory): This wire needs to be connected to a switched power source, meaning it only receives power when the ignition is on or the accessory mode is engaged.

- Ground: A solid connection to the vehicle's chassis or a dedicated ground point is essential for proper operation and to prevent electrical noise.

Here's a simplified look at common connection types:

| Tachometer Wire | Connection Point | Purpose |

|---|---|---|

| Signal | Alternator "W", ECM, Sensor | Receives engine speed data |

| Power | Ignition/Accessory Fuse | Powers the tachometer |

| Ground | Chassis/Engine Block | Completes the electrical circuit |

It's important to consult the specific Tachometer Wiring Diagram Diesel for your particular engine and tachometer model. Generic diagrams can be helpful for understanding general principles, but they won't account for the unique wiring of your setup.

To ensure you have the most accurate and reliable information for your specific project, we highly recommend referring to the manufacturer's provided Tachometer Wiring Diagram Diesel for your engine and tachometer. This is the definitive source for correct connections.