Understanding the Taco Valve Wiring Diagram is crucial for anyone dealing with hydronic heating and cooling systems. Whether you're a seasoned HVAC professional or a determined DIY enthusiast, a clear grasp of these diagrams ensures correct installation, troubleshooting, and efficient operation of your Taco valves. This article aims to demystify the Taco Valve Wiring Diagram, making it accessible and understandable for all.

What is a Taco Valve Wiring Diagram and How is it Used?

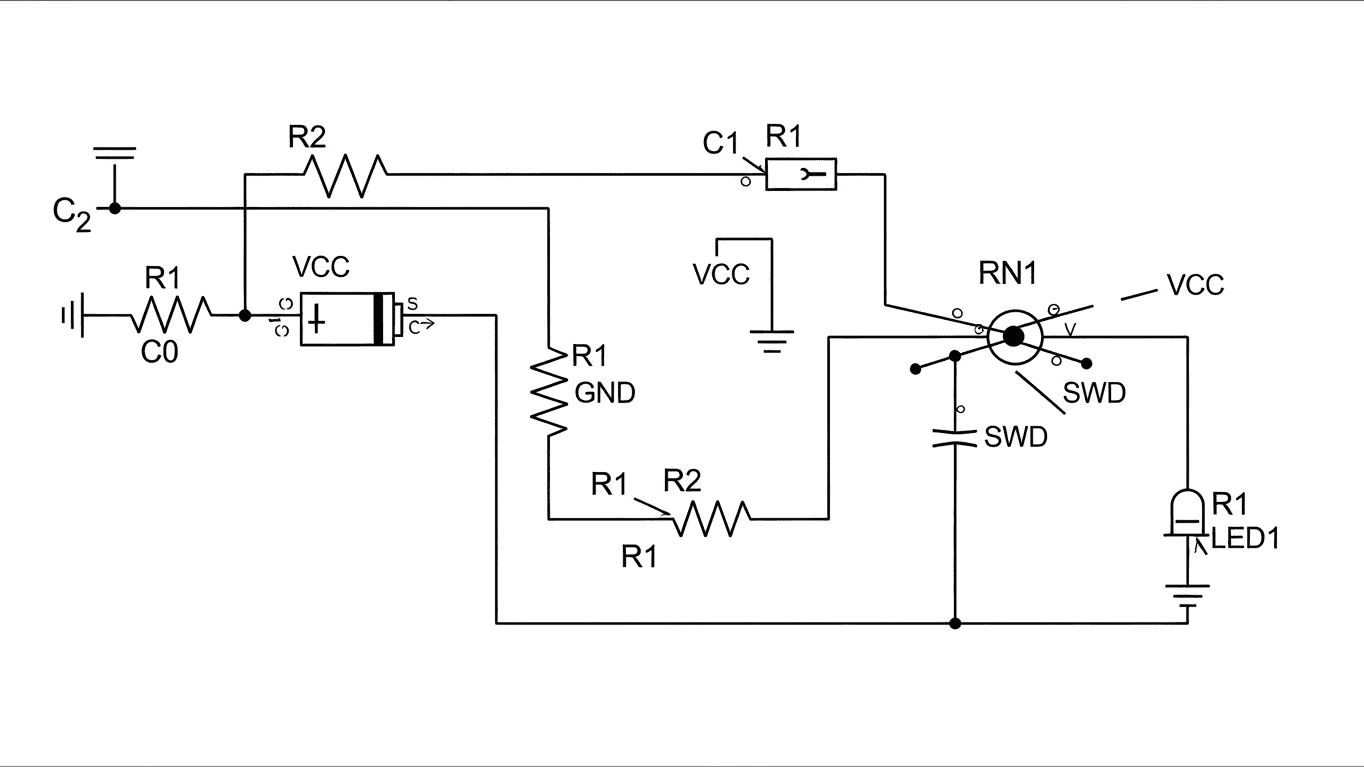

A Taco Valve Wiring Diagram is essentially a visual blueprint that illustrates how electrical components are connected to a Taco valve. These diagrams are fundamental to the proper functioning of any system that utilizes Taco valves, such as boilers, zone systems, and other hydronic controls. They detail the wiring pathways, indicating which wires connect to which terminals on the valve and its associated control devices. This level of detail is essential because incorrect wiring can lead to system malfunctions, damage to components, or even safety hazards. The importance of accurately following a Taco Valve Wiring Diagram cannot be overstated.

These diagrams serve multiple vital purposes. For installers, they are indispensable guides during the initial setup, ensuring all connections are made according to the manufacturer's specifications. For technicians performing maintenance or repairs, the Taco Valve Wiring Diagram acts as a roadmap to quickly identify potential issues and pinpoint faulty components. They also help in understanding the logic of the system, showing how the valve interacts with thermostats, control boards, pumps, and other electrical devices. To provide a clearer picture, let's consider some common elements you might find:

- Power Supply (Line and Neutral)

- Thermostat Connections

- Zone Valve Actuator Wires

- End Switch Connections

- Pump Relay Wires

The complexity of a Taco Valve Wiring Diagram can vary depending on the specific valve and the system it's part of. A simple single-zone system might have a straightforward diagram, while a multi-zone system with advanced features will naturally have a more intricate one. Each wire color and terminal designation has a specific meaning, and deviating from the diagram can lead to unexpected results. For example, a common setup involves:

- Connecting the power source to the appropriate terminals on the valve's power supply.

- Linking the thermostat's call-for-heat signal to the designated input on the valve.

- Ensuring the actuator receives power when the thermostat calls for heat.

- Utilizing end switch contacts to signal other components, like a circulator pump, to activate.

Understanding these steps through the visual aid of the diagram is key to a successful setup. A sample wiring configuration might look something like this:

| Component | Terminal on Valve | Purpose |

|---|---|---|

| Line Power | L | Provides electrical power |

| Neutral Power | N | Completes the electrical circuit |

| Thermostat Signal | T | Receives call for heat |

| Pump Relay | P | Signals pump activation |

When faced with a specific Taco Valve Wiring Diagram, it's always best to consult the manufacturer's documentation that accompanies your particular valve model. You can find comprehensive wiring guides and troubleshooting tips directly within the product manuals provided by Taco. These official resources are tailored to your specific equipment and offer the most accurate and reliable information.