Understanding a time relay wiring diagram is crucial for anyone working with automated systems, electrical controls, or even DIY projects that require delayed actions. A time relay wiring diagram serves as a blueprint, illustrating how to connect a time relay to other components in a circuit. This ensures that delays are implemented correctly and safely. Mastering the interpretation of a time relay wiring diagram opens up possibilities for sophisticated control sequences.

What is a Time Relay Wiring Diagram and How is it Used?

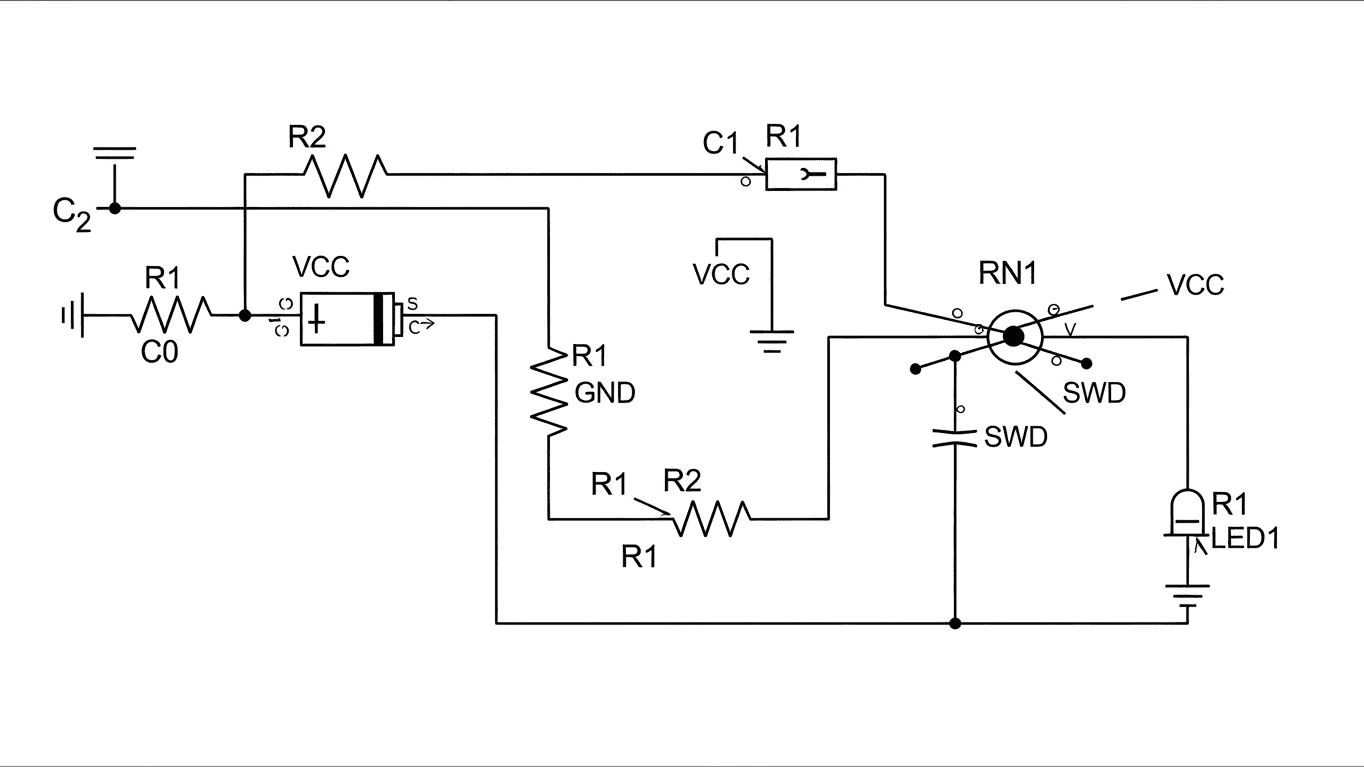

A time relay wiring diagram is a schematic representation that shows the electrical connections between a time delay relay and other parts of an electrical circuit. This diagram is essential for installing, troubleshooting, and modifying systems that rely on timed operations. Time relays, also known as timers, are devices that introduce a specific delay between the energization or de-energization of the relay coil and the change in state of its output contacts. This delay can be for a set duration, such as a few seconds or several minutes, depending on the relay's configuration.

The primary purpose of a time relay wiring diagram is to guide electricians and technicians through the proper connection process. Without it, incorrectly wiring a time relay could lead to malfunctioning equipment, electrical hazards, or even damage to the components involved. The diagram typically shows:

- The power supply connections to the relay coil.

- The trigger input, which initiates the timing sequence.

- The output contacts and how they are wired into the main control circuit.

- Any auxiliary components that are part of the timed sequence.

The importance of accurately following a time relay wiring diagram cannot be overstated for ensuring reliable and safe operation of any automated system.

Time relay wiring diagrams are used in a wide variety of applications. Here are a few examples:

- Motor Control: To start a motor after a cooling period or to sequence multiple motors.

- Lighting Systems: To turn lights on or off after a certain period, such as in stairwells or security systems.

- HVAC Systems: To control the operation of fans, compressors, and heating elements with specific delays.

- Industrial Automation: For complex sequencing in manufacturing processes.

Consider this table outlining common time relay types and their typical wiring considerations:

| Relay Type | Common Function | Wiring Highlight |

|---|---|---|

| On-Delay | Delays energization of output contacts after coil is energized. | Power to coil initiates timing; contacts close after delay. |

| Off-Delay | Maintains output contact state for a set time after coil is de-energized. | Power to coil activates output; delay starts when power is removed. |

| Interval Timer | Output is active only during the timed interval. | Both coil power and timing are involved in output activation. |

By understanding these fundamental uses and the visual representation provided by a time relay wiring diagram, users can confidently implement timed control functions. For specific installation and connection guidance, always refer to the manufacturer's provided time relay wiring diagram for your particular model.

To ensure you are using the correct connections for your specific project, please consult the official time relay wiring diagram that came with your device.