Understanding the Star Delta Starter Wiring Diagram is crucial for anyone working with three-phase induction motors, especially those designed for high starting torque applications. This wiring configuration is a fundamental technique used to reduce the starting current of a motor, thereby protecting both the motor and the electrical supply system. A correctly implemented Star Delta Starter Wiring Diagram ensures smooth acceleration and prevents voltage sags on the power line.

The Basics of Star Delta Starter Wiring Diagram

A Star Delta Starter Wiring Diagram is essentially a method for starting a three-phase induction motor by initially connecting its stator windings in a star (or wye) configuration and then, once the motor has reached a certain speed, switching the connections to a delta (or mesh) configuration. This transition is managed by a timer and a series of contactors, all interconnected according to the specific Star Delta Starter Wiring Diagram. The primary goal is to reduce the voltage applied to the motor windings during startup. In a star connection, each winding receives only 1/√3 (approximately 58%) of the line voltage. This significantly lowers the inrush current, which can otherwise be six to eight times the motor's full load current. The importance of managing this inrush current cannot be overstated for the longevity of the motor and the stability of the power grid.

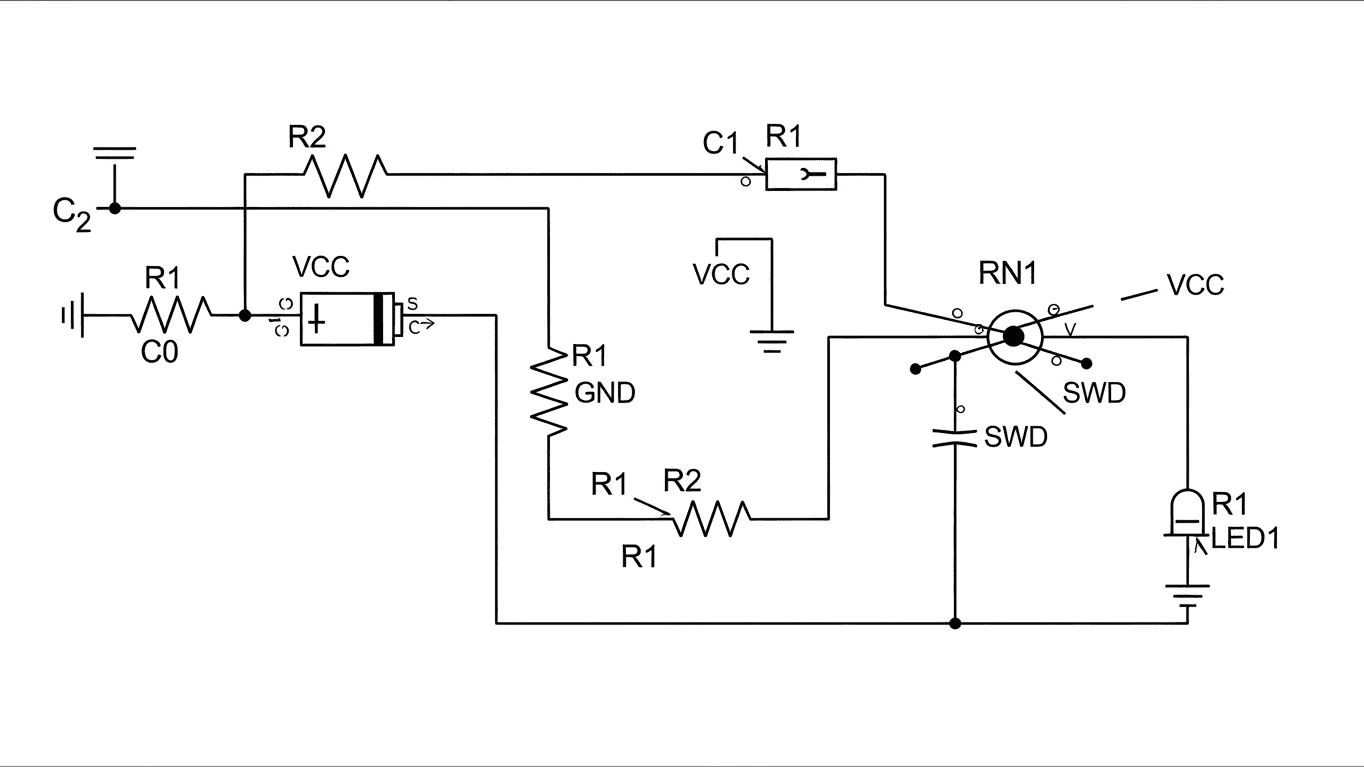

The components involved in a typical Star Delta Starter Wiring Diagram include:

- Three contactors: Main, Star, and Delta contactors.

- A thermal overload relay for motor protection.

- A timer to control the transition from star to delta.

- The three-phase motor itself.

The sequence of operation is critical. Initially, the main and star contactors close, applying power in a star configuration. After a predetermined time interval set by the timer, the star contactor opens, and the delta contactor closes. This reconfigures the windings into a delta connection, where each winding now receives the full line voltage. This provides the necessary torque for the motor to accelerate to its operating speed. The transition is designed to be seamless, minimizing any dip in torque during the changeover.

| Connection | Voltage per Winding | Starting Current Reduction |

|---|---|---|

| Star | Line Voltage / √3 | Approximately 1/3 of Delta starting current |

| Delta | Line Voltage | Full starting current |

This method is particularly beneficial for squirrel cage induction motors that require high starting torque, such as those used in pumps, fans, and compressors. By reducing the starting current, it allows for smaller electrical supply infrastructure and prevents nuisance tripping of circuit breakers. The Star Delta Starter Wiring Diagram, when followed precisely, ensures that the motor starts smoothly and efficiently, extending its operational life and reducing maintenance requirements.

For a comprehensive understanding and practical application, it is highly recommended to refer to a detailed and accurate Star Delta Starter Wiring Diagram. The visual representation provided in such diagrams simplifies the complex interconnections and clarifies the operational sequence. Please use the resources available to study a proper Star Delta Starter Wiring Diagram.