Understanding the Start Run Capacitor Wiring Diagram is crucial for anyone dealing with electric motors in appliances and machinery. This diagram is a blueprint, guiding the proper connection of these vital components to ensure a motor starts efficiently and runs smoothly. Without a clear grasp of the Start Run Capacitor Wiring Diagram, troubleshooting motor issues or performing repairs can be a daunting and potentially hazardous task.

The Role of Capacitors in Motor Operation

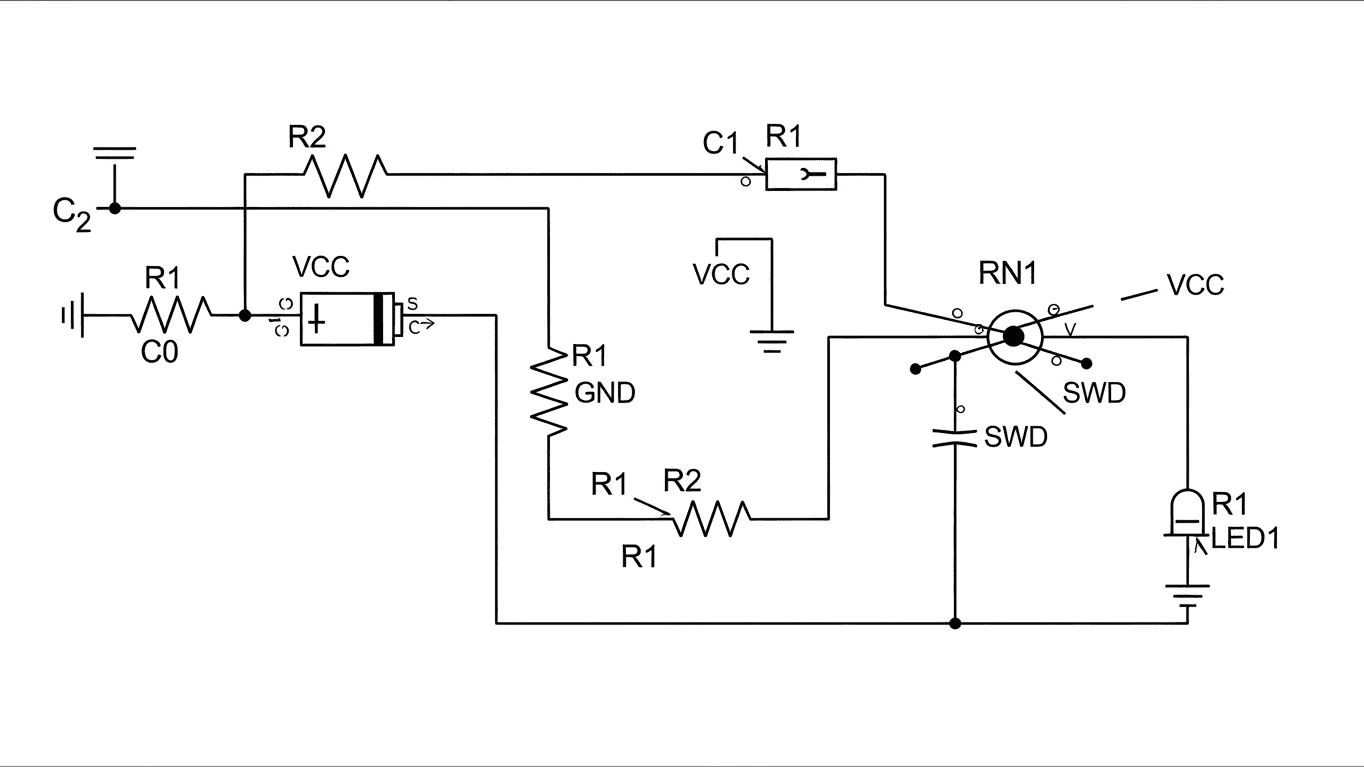

Electric motors, particularly single-phase AC motors, require assistance to overcome their initial inertia and get rotating. This is where start and run capacitors come into play. A start capacitor provides a significant burst of energy to get the motor spinning, while a run capacitor helps maintain the motor's rotation by smoothing out the power supply and improving efficiency. The Start Run Capacitor Wiring Diagram illustrates how these components are interconnected with the motor's windings and the power source.

The Start Run Capacitor Wiring Diagram typically shows two distinct types of capacitors, though some motors might use a dual-run capacitor that combines both functions. The start capacitor is generally a larger, electrolytic type and is only active during the initial startup phase. Once the motor reaches a certain speed, a centrifugal switch or a potential relay disconnects the start capacitor. The run capacitor, often smaller and of a different type (like a film capacitor), remains connected throughout the motor's operation to ensure continuous and stable running. Here's a simplified breakdown:

- Start Capacitor: Provides extra torque for startup.

- Run Capacitor: Improves efficiency and smooth running.

- Centrifugal Switch/Relay: Disengages the start capacitor.

The proper wiring of these capacitors as depicted in the Start Run Capacitor Wiring Diagram is absolutely essential for the longevity and performance of the motor. Incorrect connections can lead to motor failure, overheating, or failure to start altogether. For example, a faulty start capacitor might prevent a compressor from kicking on, while a bad run capacitor could cause a fan motor to hum but not spin effectively.

When examining a Start Run Capacitor Wiring Diagram, you'll notice connections to the motor's main winding, auxiliary (start) winding, and the power supply. Understanding the labels and symbols on the diagram is key. For instance, "M" often denotes the main winding, "S" the start winding, and "C" the common terminal. The wiring itself will involve connecting the capacitors in series or parallel with specific windings, depending on the motor design. A typical scenario involves:

| Component | Connection Point |

|---|---|

| Start Capacitor | In series with the start winding and controlled by a switch. |

| Run Capacitor | In parallel with the main winding. |

| Power Supply | Connected to common and one of the windings (often main). |

It is highly recommended to consult the specific Start Run Capacitor Wiring Diagram provided by the manufacturer for your particular appliance or motor. This ensures you are following the most accurate and safe procedure for replacement or troubleshooting. The information presented here is a general overview to help you understand the fundamental principles.

To get the most accurate and specific guidance for your situation, please refer to the manufacturer's documentation for your appliance or motor, which will contain the precise Start Run Capacitor Wiring Diagram you need.