Understanding the Start/run Capacitor Wiring Diagram is crucial for anyone working with electric motors that require a little extra oomph to get going and keep running smoothly. This diagram acts as a blueprint, guiding you through the correct connections to ensure your motor operates efficiently and safely. A properly understood Start/run Capacitor Wiring Diagram is key to a healthy motor.

The Heart of Motor Starting and Running

A start/run capacitor, often found in single-phase AC motors, plays a vital role in motor operation. Single-phase motors lack an inherent starting torque, meaning they can't begin to rotate on their own. This is where the start capacitor comes in. It provides a temporary, extra push to get the motor spinning. Once the motor reaches a certain speed, the start capacitor is typically disconnected from the circuit, often by a centrifugal switch or a potential relay. The run capacitor, on the other hand, is permanently connected and remains in the circuit. Its purpose is to improve the motor's efficiency, power factor, and running performance by creating a more balanced rotating magnetic field. The correct wiring of these components is incredibly important for motor longevity and performance.

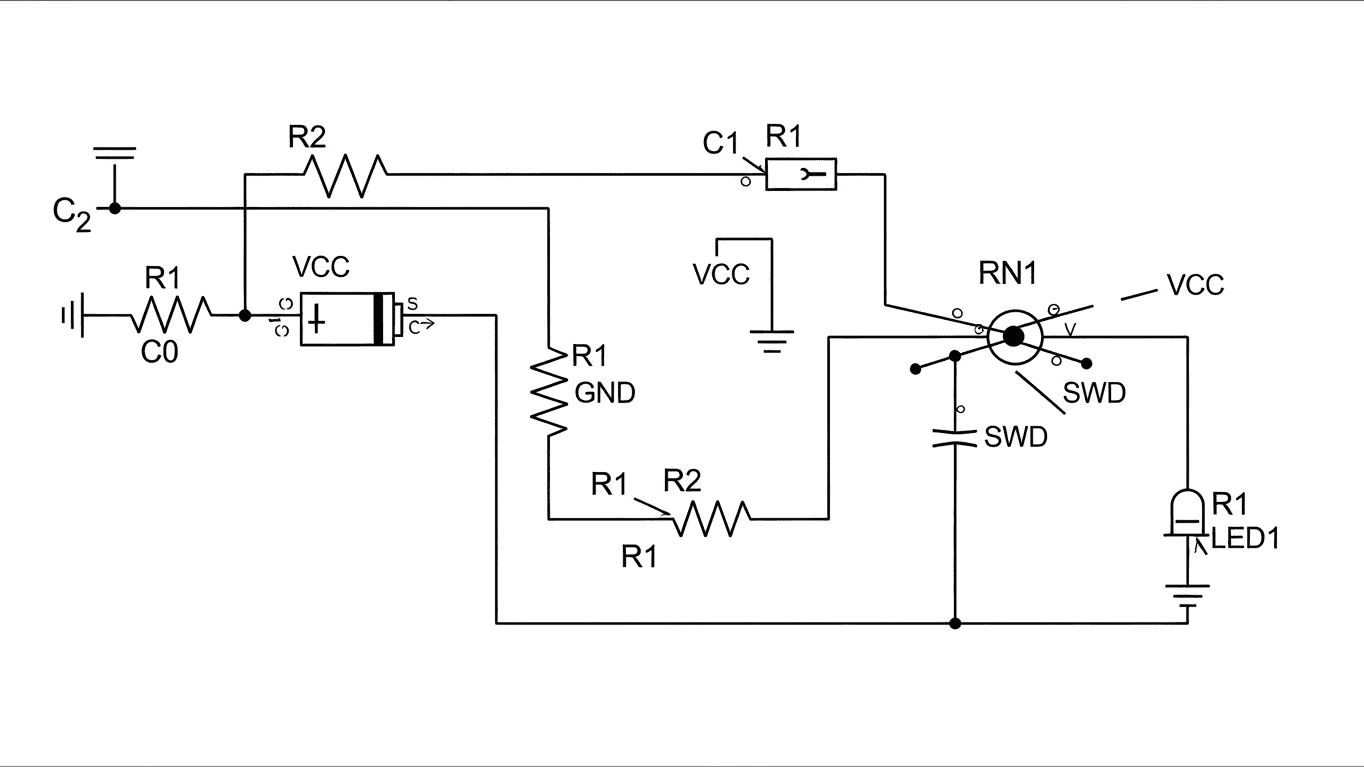

The Start/run Capacitor Wiring Diagram illustrates how these two components work in tandem. Generally, you'll see the motor's main windings (often referred to as the run winding) and auxiliary windings (start winding). The run capacitor is wired in parallel with the motor's main winding. The start capacitor is wired in series with the start winding, and this entire combination (start winding and start capacitor) is connected in parallel with the main winding. A centrifugal switch or relay is placed in series with the start capacitor to break the circuit once the motor is up to speed. Here's a simplified look at the typical connections:

- Line (Hot) Wire

- Neutral Wire

- Motor Terminals (Common, Start, Run)

- Start Capacitor

- Run Capacitor

- Centrifugal Switch/Potential Relay

The specific arrangement can vary slightly depending on the motor type and manufacturer, but the fundamental principle remains the same: providing an initial boost and then optimizing running conditions. The diagram ensures that the start capacitor only engages during the initial startup phase, preventing it from overheating or damaging the motor if left connected. The run capacitor's continuous presence ensures optimal efficiency throughout the motor's operation. A typical sequence might look like this:

- Power is applied to the motor.

- The start winding and start capacitor create a phase shift, providing starting torque.

- As the motor accelerates, the centrifugal switch or relay opens, disconnecting the start capacitor.

- The run capacitor remains in the circuit, improving the motor's running performance.

If you are dealing with a faulty motor or are planning on replacing a capacitor, it is highly recommended to consult the specific Start/run Capacitor Wiring Diagram for your appliance or motor model. This detailed diagram will prevent incorrect connections that could lead to motor damage, electrical hazards, or simply a motor that won't start or run correctly. Many manufacturers provide these diagrams on the motor's casing, in the appliance's user manual, or on their official websites.

For accurate and safe electrical work, always refer to the specific Start/run Capacitor Wiring Diagram provided by the manufacturer of your appliance or motor. This is the most reliable source for ensuring correct connections and preventing damage or injury.