Understanding a Stepper Wiring Diagram is your key to unlocking precise motion control in a wide range of electronic projects. Whether you're building a 3D printer, a CNC machine, or an automated robotics system, knowing how to correctly connect your stepper motor is fundamental. This guide will demystify the stepper wiring diagram, making it accessible even if you're new to electronics.

Decoding the Stepper Motor Connections

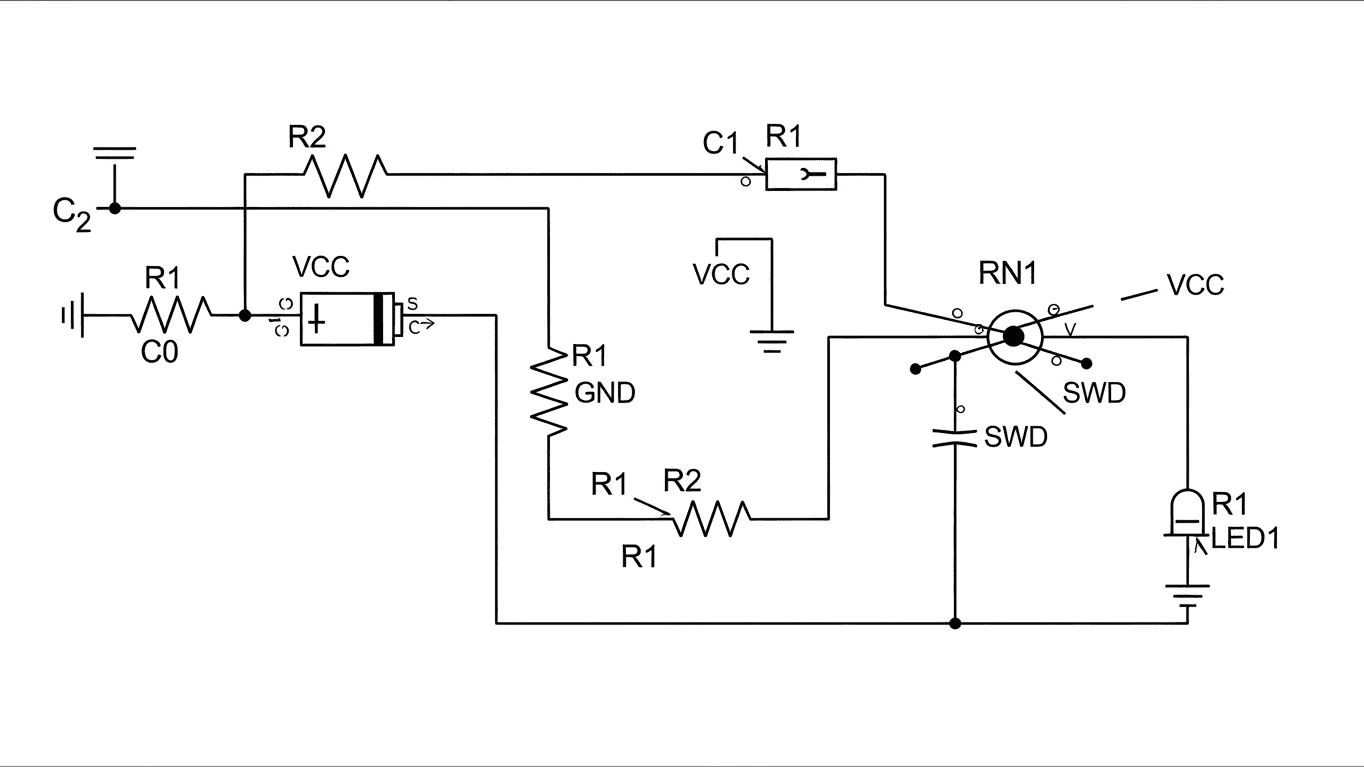

At its core, a stepper motor is an electric motor that divides a full rotation into a number of equal steps. Unlike DC motors that spin continuously, stepper motors move in discrete steps. A Stepper Wiring Diagram is essentially a blueprint that illustrates how to connect the motor's coils to a power source or a motor driver. This diagram is crucial because stepper motors typically have multiple wires, and connecting them incorrectly can lead to the motor not moving, moving erratically, or even sustaining damage. The diagram guides you through identifying the different coils within the motor and how they should be energized in sequence to achieve controlled rotation.

Stepper motors are commonly found in applications demanding high precision and repeatability. For instance, in a 3D printer's X, Y, and Z axes, stepper motors are used to move the print head and build platform with exact accuracy. In CNC machines, they drive the cutting tools along precise paths. The Stepper Wiring Diagram helps differentiate between the common types of stepper motors, such as unipolar and bipolar motors. Unipolar motors often have more wires and can be driven with simpler circuitry, while bipolar motors, though sometimes requiring more complex drivers, generally offer higher torque and efficiency.

The complexity of a Stepper Wiring Diagram often depends on the motor's internal configuration. A typical bipolar stepper motor has four wires, representing two independent coils. A common way to illustrate these connections is through a simple diagram showing:

- Coil A+ and Coil A-

- Coil B+ and Coil B-

For unipolar motors, you might see additional common wires for each coil. The driver circuit then interprets the Stepper Wiring Diagram to send the correct sequence of electrical pulses to these coils. This sequence dictates the direction and the number of steps the motor takes. A simplified table illustrating a common bipolar stepper motor wiring might look like this:

| Motor Wire Color (Example) | Coil Connection |

|---|---|

| Red | Coil A+ |

| Blue | Coil A- |

| Green | Coil B+ |

| Black | Coil B- |

Accurate wiring based on the diagram is paramount for the proper functioning and longevity of your stepper motor and its associated electronics.

To ensure you have the correct connections for your specific stepper motor and driver, always refer to the detailed documentation provided with your components. This article serves as a foundational understanding, but the specific manufacturer's Stepper Wiring Diagram is the definitive guide for your project.