Understanding a tach wiring diagram is crucial for anyone working with automotive or industrial engines. A tach wiring diagram acts as a blueprint, showing precisely how the tachometer, or "tach," connects to the engine's ignition system or electronic control unit (ECU). This diagram is your essential guide to ensuring accurate engine speed readings and proper tachometer functionality.

What is a Tach Wiring Diagram and How is it Used?

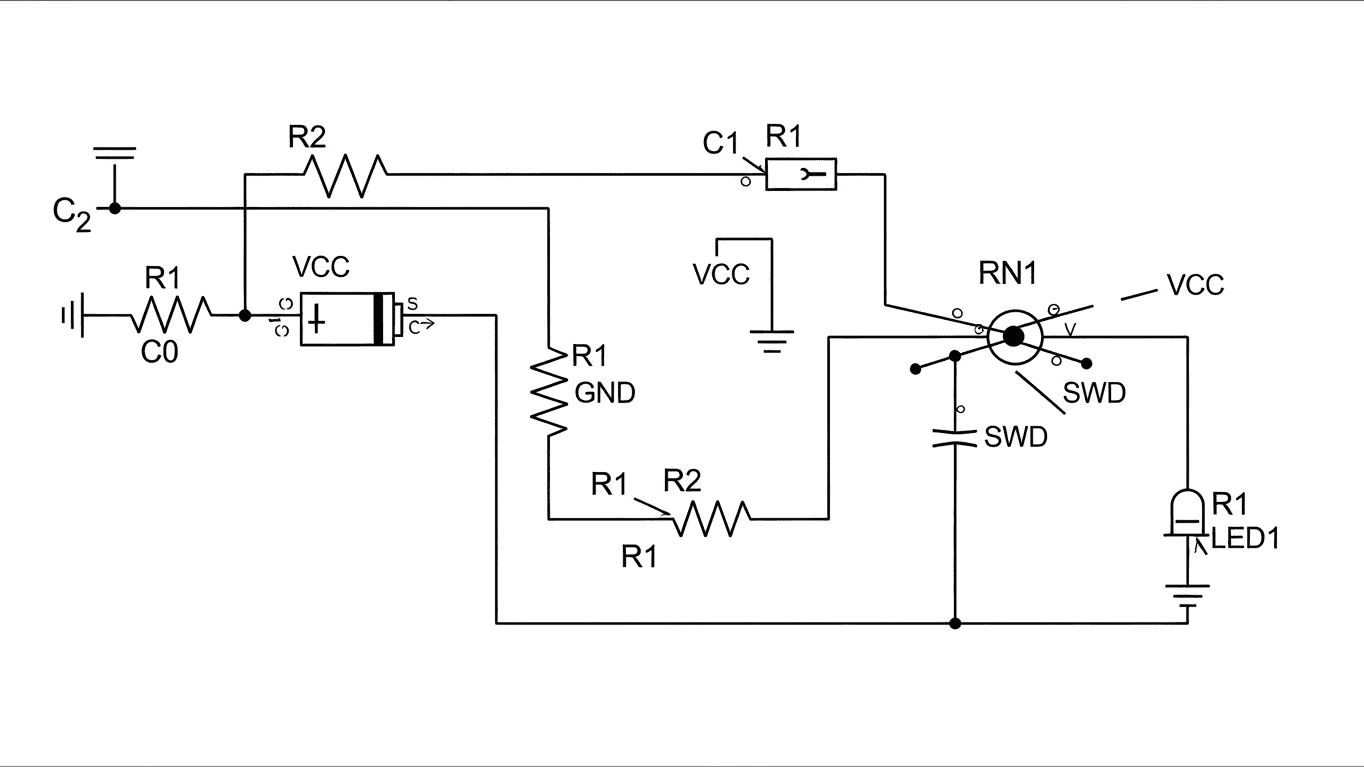

A tach wiring diagram is a schematic illustration that details the electrical connections required to install and operate a tachometer. A tachometer is an instrument used to measure the rotational speed of an engine, typically in revolutions per minute (RPM). The diagram shows you which wires from the tachometer connect to specific points on your engine or vehicle's electrical system. These connection points can vary significantly depending on the type of ignition system your engine uses. For example, older vehicles with breaker points may have a different connection than modern vehicles with electronic ignition or direct ignition systems. Knowing these differences is key to a successful installation. The importance of following the correct tach wiring diagram cannot be overstated; incorrect wiring can lead to inaccurate readings, damage to the tachometer, or even harm to your engine's control systems.

Tach wiring diagrams are used in several key scenarios. Firstly, they are essential during the installation of a new tachometer. Whether you're adding an aftermarket tachometer to your classic car or replacing a faulty one, the diagram guides you through the process. Secondly, they are invaluable for troubleshooting. If your tachometer is not working, giving erratic readings, or showing no signal, consulting the wiring diagram allows you to trace the connections and identify potential breaks, shorts, or loose connections. Finally, they are useful for understanding how the tachometer obtains its signal. Generally, the tachometer receives its signal from:

- The negative terminal of the ignition coil

- A dedicated tachometer output from the ECU

- An alternator (in some diesel engines)

The specific method depends on the engine's design and the type of tachometer you are using. For instance, a simple points-based system might send a pulse to the tachometer for each spark event. A modern ECU might have a dedicated circuit that sends precise RPM data. Below is a simplified representation of common connection points:

| Tachometer Terminal | Typical Engine Connection |

|---|---|

| Signal (SIG) | Ignition Coil Negative (-) or ECU Tach Output |

| Ground (GND) | Vehicle Chassis Ground |

| Power (12V+) | Ignition Switched Power (ACC or ON) |

Understanding these components and their relationship as depicted in the diagram is fundamental. Most tachometers will have at least three wires: a power wire, a ground wire, and a signal wire. The power wire connects to a source that provides 12-volt power when the ignition is on or in accessory mode. The ground wire connects to a reliable chassis ground. The signal wire is the most critical, as it receives the engine speed pulse. The exact location and type of signal source will be clearly indicated on a specific tach wiring diagram for your vehicle or engine model. Always refer to the manufacturer's diagram for your specific tachometer and vehicle for accurate installation and troubleshooting guidance.

Now that you have a better grasp of tach wiring diagrams, dive into the specific resources available to help you with your project. You can find detailed information tailored to your exact needs by referring to the diagrams provided in the sections that follow this article.