Understanding a Stepper Motor Wiring Diagram is crucial for anyone looking to integrate stepper motors into their projects. Whether you're building a 3D printer, a CNC machine, or a custom automation system, knowing how to correctly connect these motors is the first step to success. This guide will demystify the Stepper Motor Wiring Diagram and help you get your motors spinning accurately.

The Essentials of a Stepper Motor Wiring Diagram

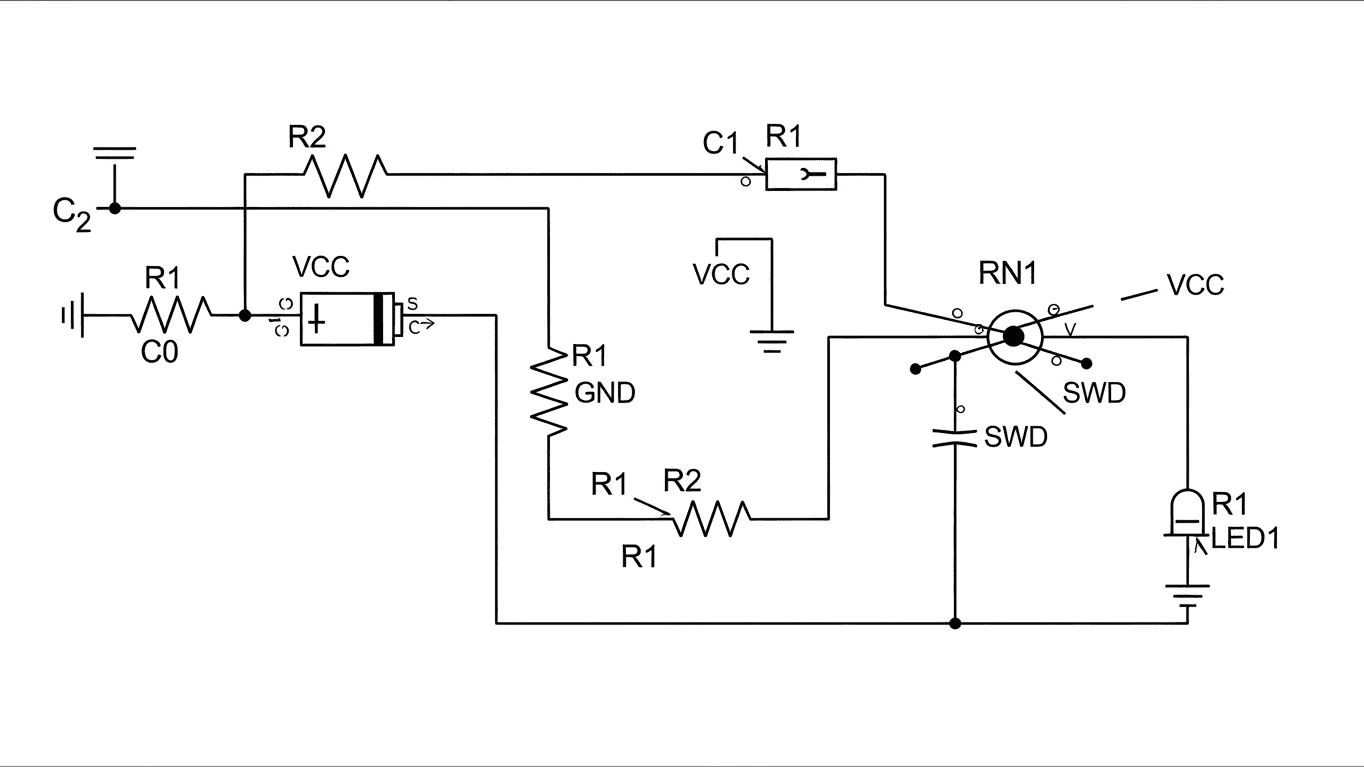

A stepper motor wiring diagram acts as a blueprint, illustrating how the coils within the motor are connected and how they should be energized to achieve precise rotational movement. Unlike regular DC motors that spin continuously when power is applied, stepper motors move in discrete steps. This stepping action is controlled by energizing specific coil pairs in a sequence. A typical stepper motor has four, five, six, or eight wires, each representing a connection to an internal coil winding.

The primary purpose of a stepper motor wiring diagram is to identify these coil windings and their corresponding wires. This is vital because stepper motors can be wired in different configurations, and the correct wiring ensures optimal performance and prevents damage. Here are the common types of stepper motors and how their wiring relates to the diagram:

- Unipolar Stepper Motors: These motors have center-tapped coils, allowing for simpler driving electronics. The diagram will show the center taps and the ends of the coils.

- Bipolar Stepper Motors: These are more common and have two separate windings. The diagram will clearly distinguish between the two independent windings.

The accuracy of the Stepper Motor Wiring Diagram is paramount for ensuring your motor operates as intended and avoids potential burnout or jerky movements.

When you encounter a Stepper Motor Wiring Diagram, you'll typically see symbols representing the motor coils and the wires. The diagram will often show how these coils are grouped. For bipolar motors, the windings are usually labeled as A and B, with each winding having two wires. For unipolar motors, you might see labels like A, A', B, and B', with center taps often denoted by a dot or a separate line.

Here’s a simplified representation of common wiring scenarios you might see:

| Motor Type | Common Wire Count | Wiring Goal |

|---|---|---|

| Bipolar (4-wire) | 4 | Connect the two coils to a bipolar driver. |

| Unipolar (6-wire) | 6 | Can be wired as bipolar or unipolar. Diagram shows center taps. |

To successfully wire your stepper motor, consult the specific diagram provided with your motor or its datasheet. This diagram will detail the color coding of the wires and how they correspond to the internal coils, enabling you to connect them to your motor driver correctly.

To gain hands-on experience and see these concepts in action, refer to the comprehensive diagrams and explanations found in the Stepper Motor Wiring Guide provided by your motor manufacturer or a reputable electronics supplier.